Further drivers are the low-security requirements across the globe, the growth of the automobile industry, increasing financial services market, and rising GDP rates of developing countries. With terrorist attacks and increasing security concerns especially in the US and in Africa, governments are aiming at minimizing risk. The main drivers of resistant glass are the rising safety and security concerns globally, which are expected to further accelerate within the next five to six years. Place these side by side and create a 100 Ballistic Partition Designed to overlap and interlock for ZERO Ballistic. Security concerns are driving demand for bulletproof glass worldwide At all times our ballistic glass delivers optimal visibility. Applications involve vehicles as well as buildings (such as governmental offices and embassies), and marine applications. In spite of these figures, the Middle East and Africa are expecting to experience highest CAGR during the forecast. Our transparent armor is made for both military and civilian security and defense applications. North America is taking the lead, followed by Europe. The dominating market for transparent armor is North America, which makes up 26.8% of the overall market. The transparent armor is mostly applied for security purposes as security needs are increasing worldwide. We also manufacture laminated to meet your specific threat or standards specifications. The main factors that determine the kind of glass are its thickness and end-users demand. Patriot Armor Glass Laminates meet NIJ and UL standards for bullet-resistant applications. Manufacturers of bulletproof glass are constantly conducting research to develop even better technologies for the glass. The stronger glass is used in banks, cash trucks, ATM booths, residential buildings and premium vehicles. Typical end users of bulletproof glass are the governmental services industry, financial services industry, automotive industry, construction industry and aerospace industry.

BALLISTIC GLASS AND ARMOR CODE

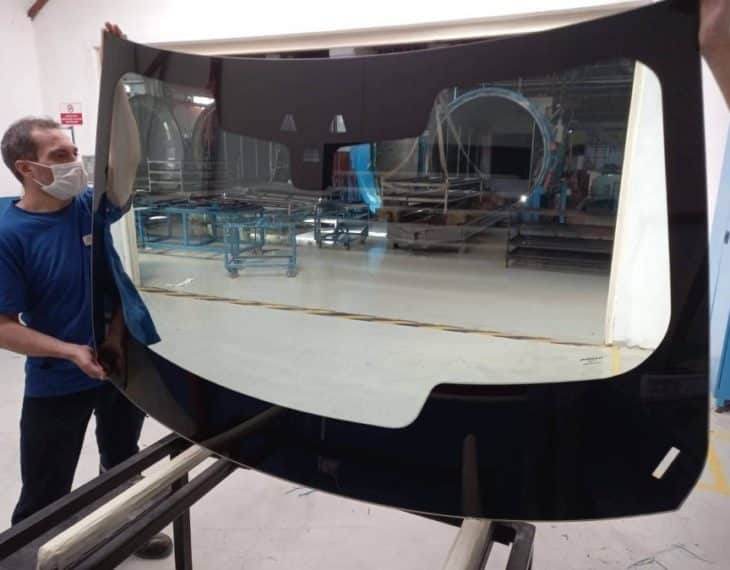

As a result, the bullet slows down that it loses its energy to pierce through the glass Fibrillation of fibers (front view, code 2F-1). As the energy is divided between different components of this glass, it can be quickly absorbed. To show how it works when a bullet strikes bulletproof glass, the energy of the security glass spreads out sideways through the layers. Another word for the layers is laminate, which can be up to eight times thicker than a single pane and is obviously much heavier. To describe it more precisely, it is made up of layers of polycarbonate that are sandwiched in between pieces of toughened glass. In the manufacturing stage of ballistic glass, polycarbonate, acrylic, glass-clad polycarbonate and thermoplastic materials are added in order to ensure a high resistance from bullets.īulletproof Glass is different to ordinary glass. Usually, the bulletproof glass contains one to two kinds of glasses, hard and soft. Bulletproof glass is very resistant and can withstand damages that occur from small projectiles and bullets. Bulletproof glass, which is also known as bullet-resistant glass, ballistic glass and transparent armor, consists of transparent materials.

0 kommentar(er)

0 kommentar(er)